The term recycling loop encompasses the process that a resource, material or product goes through from its production, through its use, to its reprocessing and subsequent possible reuse. The concept behind a long-term and full circular economy is that the recycling loop is completely closed in itself, and thus no new natural resources need to be expended in the production of new goods.[1] The recycling loop is the process by which a resource, material or product is recycled.

A distinction is made between three types of recycling cycles:

- Production waste recycling: Here, recycling already takes place during production. Materials that arise as a waste product during production are reprocessed for other purposes.

Product recycling: The product is recycled and reused while maintaining the same condition.

Substance recycling: If recycling takes place after the product has been used, i.e. the product is broken down into its individual raw materials and returned to the cycle for further use, this is referred to as substance recycling.[2] The product is recycled and reused for other purposes.

The different types of recycling

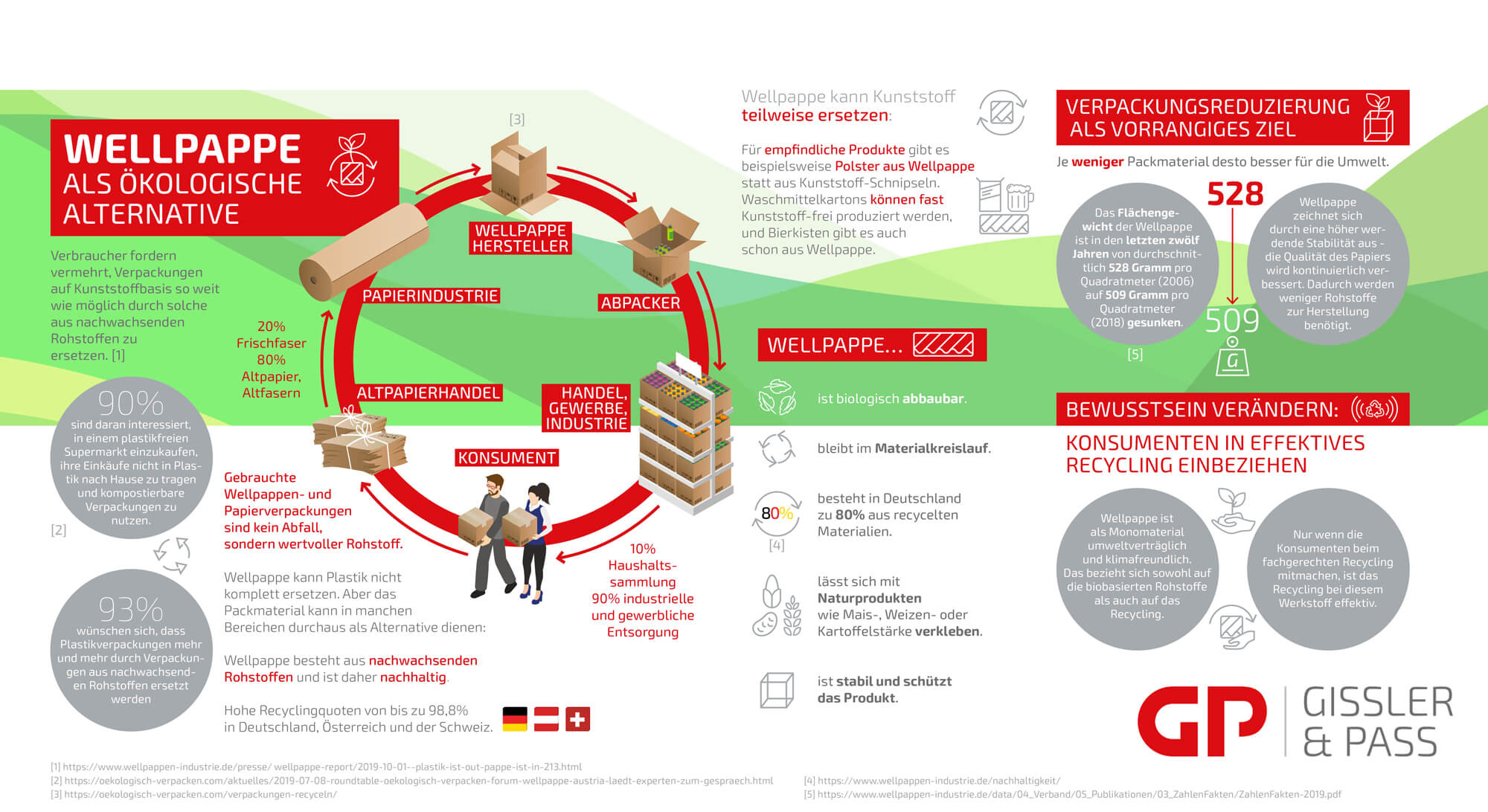

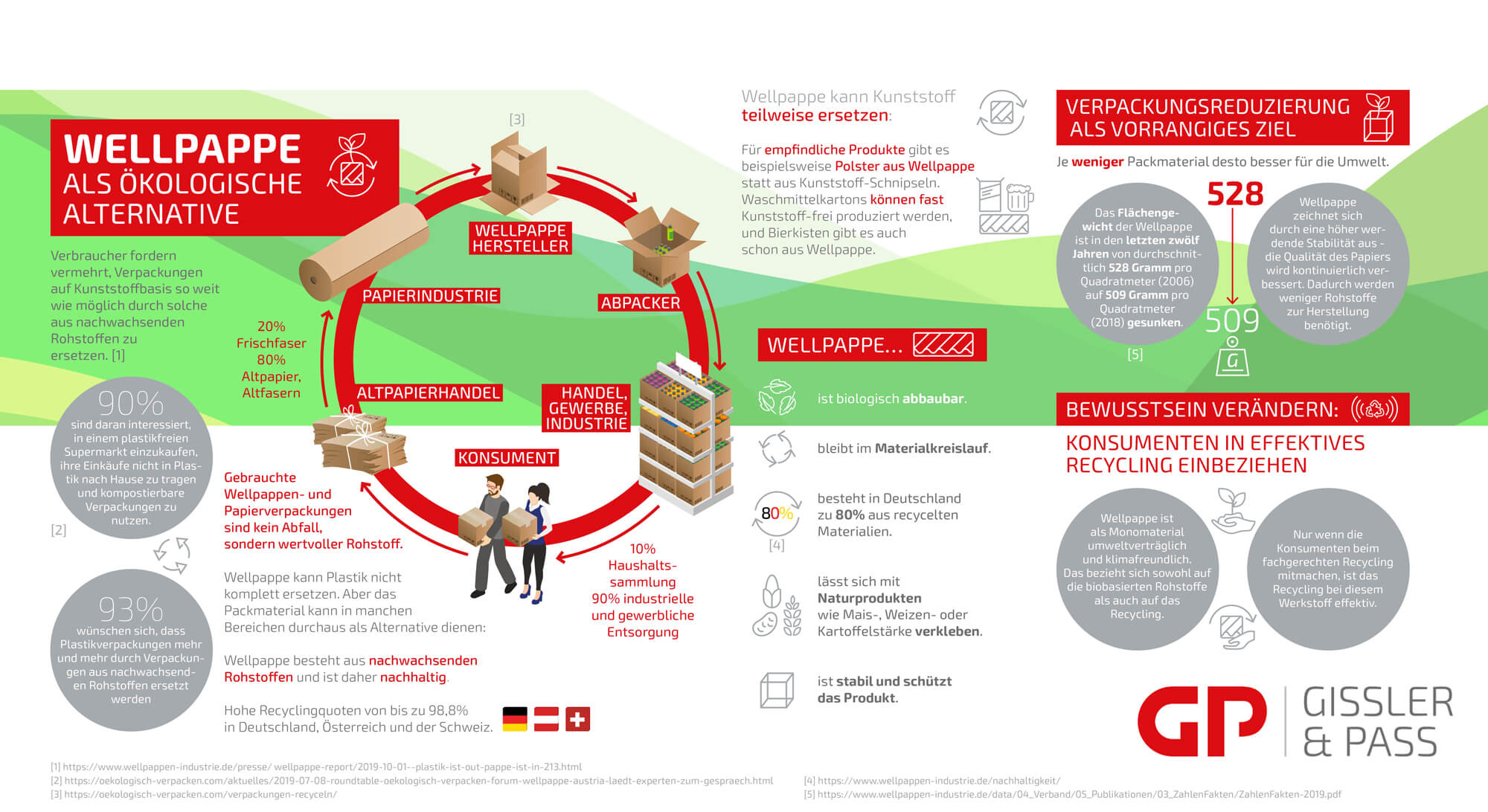

Recycling: In this process, discarded materials are reprocessed into new products. Depending on the process and material, the original product is converted back into a valuable material and made usable for renewed production. Recycling takes place with aluminium cans, plastic bottles and paper-based packaging, among others. Waste paper in particular is an important element in the recycling process, almost 100% of which passes through the further material cycle. This can be used for the further production of corrugated board, so that corrugated board packaging and materials already consist of about 80% waste paper.

Reuse: In reuse, a material or product is reprocessed and used again after it has been used for its original purpose. In this case, the product has usually only been changed in the most minimal way. Examples include used cars, refurbished electronics and clothing.

Upcycling: In upcycling, recyclable materials and products are reused in a modified form, i.e. the new intended use is different from the original. Typical upcycling products are Euro pallets that are converted into furniture and car tyres that are used as swings and seesaw elements.[3]

- Recycling processes and the methods used differ depending on the material. The following recycling process uses waste paper to illustrate the individual steps:

- In the first step, the waste paper is collected, recorded and meticulously sorted according to colour, type and thickness.

- The paper then enters the filter system, which uses large screens to remove non-paper materials (e.g. paper clips, staples, plastic parts) from the material.

- The paper is then shredded by machine and soaked in water. This breaks it down into its individual fibre components and filters out other foreign substances.

- With light-coloured paper, the printing ink is removed by a sodium hydroxide solution and surfactants and the paper is lightened within a bleaching process.

- Further fillers and additives, including fresh fibres, are now added to the resulting paper pulp.

- The final step involves pressing the paper pulp through a roller, after which the paper is dried and rolled up.[4]

Example for Reycycling cycle

[1] Vgl. wikipedia.de (Stand: 23.02.20): Recyclingkreislauf, https://de.wikipedia.org/wiki/Recyclingkreislauf, aufgerufen am 07.08.20

[2] Vgl. entsorgbar.ch (Stand: 07.08.20): https://www.entsorgbar.ch/recycling-rocks/recyclingkreislauf, aufgerufen am 07.08.20

[3] Vgl. https://www.terracycle.com/de-DE/ (Stand: 08.08.20): Entsorgungsszenarien für Produkte und Wertstoffe, https://www.terracycle.com/de-DE/pages/recycling-begriffe-und-definitionen, aufgerufen am 08.08.20

[4] Vgl. lichtblick.de (Stand: 21.10.2019): Des Papiers neue Kleider: Das passiert beim Recycling, https://www.lichtblick.de/magazin/recycling-upcycling/altpapier-recycling, aufgerufen am 08.08.20